With an international brand and a quality that the market is willing to pay more for, it simply doesn’t make sense to move your production away from one of Europe’s leading environments within material and manufacturing technology.

![]()

ISIFLO AS is a wholly-owned subsidiary of the Dutch industry group Aalberts and part of an international network comprising 16,000 employees across 151 locations and with a turnover of NOK 30 billion. Their main product is couplings for pipes within water, sewage and gas supply and the brand name 'ISIFLO' is among one of the strongest in its category in Europe. As the market leader in Scandinavia, Germany and France, the company has 161 employees and a turnover of around NOK 550 million – all managed from the Industrial Park at Raufoss.

Their journey began in 1969 when engineer and inventor Arvid Helland turned to what was then the RA Group to sell the patent rights for a plastic pipe coupling. Today, their modern production lines produce around 400,000 pipe couplings in a composite material and about 2.2 million couplings in brass each year. This is the result of a development project undertaken in close collaboration between their own R&D department, experts from raw material manufacturers, institutes, national and international producers of plastic products and not least their partners right here at the park – the other companies!

Informal learning

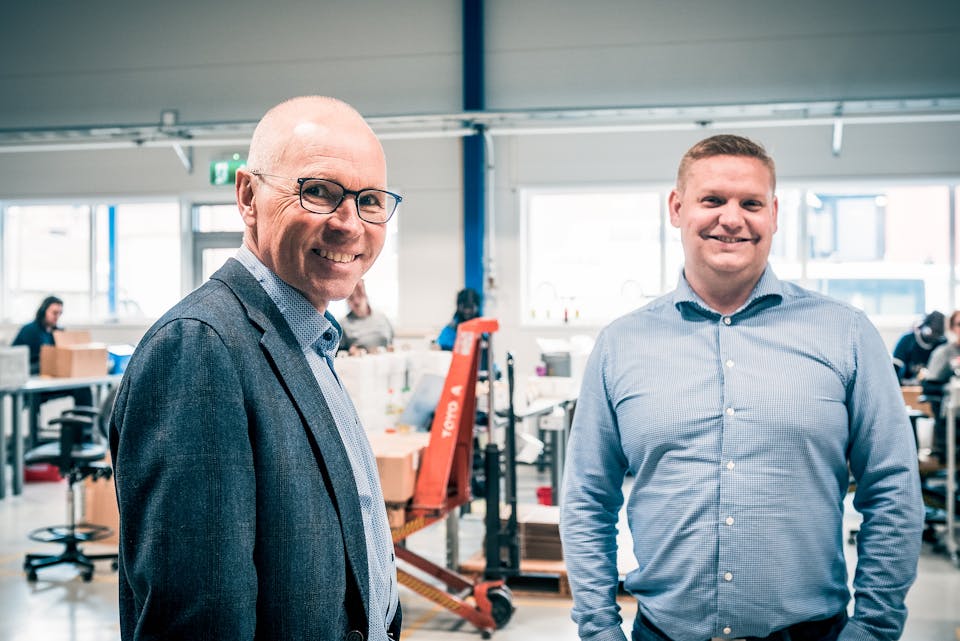

"The Raufoss environment is unique within an industrial context; I do not know of any other place with the same formal and informal networks, where companies are able to work so closely together. Simply being a tenant at Raufoss Industrial Park can save you large sums on expensive consultants," Lars Ølstad, CEO of ISIFLO AS, says with a smile. It was 30 years ago that the then freshly graduated industrial economist from Fetsund started his job with RA. "I don’t think you’ll find anywhere else in Norway with such an exciting international working environment coupled with access to the forest right on your doorstep". And with respect to working internationally, Ølstad knows what he’s talking about as a local record-holder for the number of trips taken back and forth from Gardermoen. "Young people with ambitions ought to look no further than the industry; it’s here the most exciting future opportunities will lie and here in the Innlandet region you truly can have it all in terms of both career and recreation."

The next generation

One of the young and upcoming talents at the company is CFO Hans Kristian Rønningen. Well established in Stuttgart, he was head-hunted back home to manage the finance department, a decision he has never regretted. With a product development process in the midst of an exciting technological overhaul and investments in the order of NOK 130 million in made-to-order buildings and equipment, his working day is both highly challenging and incredibly exciting.

"You can tell that the international owners really do understand the value of the culture and the competencies that they have here at Raufoss. Investments of this magnitude simply would not be made if it weren’t for a serious belief that the industry right here is better suited than anywhere else in the world to deliver the goods. We need to deliver on price and quality, but that’s a combination which we understand very well here at Raufoss", says Rønningen.

Developer

Together with the administration here at Raufoss Industrial Park, the civil economist is responsible for all investments connected to and the planning of a development project that will encompass a total of 9,000 m2 and bring the entirety of ISIFLO together under one tenancy. 40 million in warehouses and 20 million in administration buildings is no short order. "As the buyer of a construction project of this magnitude, it’s reassuring to feel that we’re all in the same boat. The new owners of the park are very interested in what’s going on; they are on the ball and you can tell that they have a feel for the project. It is good to have a partner in an administration that has competencies within these kinds of processes and development projects. Naturally there is of course some discussion about the tenancy and the distribution of costs, but it never feels like you’ve got to squeeze the lemon for that very last drop", says Rønningen with a smile. "The new owners deserve praise for their work at the park and their willingness to invest in things that were previously overlooked, says Ølstad who knows what he’s talking about after working with countless different ownership constellations at the park.

Safeguarding a culture

The value of a building can be calculated in monetary terms, but how can you put a price on the culture that comes with the deal? 125 years of industrial community and world-leading competencies within mass production is freely available just a few metres down the street. As a newcomer to Raufoss industry, Rønningen doesn’t know the history as well as his boss, but he confirms that it’s a heritage worth nurturing.

"It’s now up to my generation to take responsibility for the continuation of this collaborative attitude. For there is no doubt that the cohesion which exists here is the secret formula behind so much success and one of the reasons that we are able to compete on a global scale from the woodlands of Raufoss. Letting this attitude disappear along with the old employees who started during the time of the RA Group would be to lose a tremendous resource.

Christmas in new surroundings

The new building is due for completion in December 2020 and with that the next 25 years will be set for further industrial innovation, knowledge sharing and development here at Raufoss Industrial Park. Considerable value will be generated here through the supply of environmentally-friendly Norwegian products of the highest quality from one of the most innovative and internationally-oriented industrial parks in the country.